- Posts: 4403

Building a manual pick&Place machine

- PhracturedBlue

-

Topic Author

- Offline

Less

More

08 Apr 2015 20:23 #30914

by PhracturedBlue

Buildinga manual pick&Place machine was created by PhracturedBlue

After building 3 of the UniversalTx boards with tweezers, I was getting really fed-up with that method. While there are some open-source fully-automated P&P machines in development, nothing really ready to go now, and they are quite expensive. Manual machines are also quite expensive to buy. SadSack posted this link in the UniversalTx thread:

vpapanik.blogspot.gr/2012/11/low-budget-...-pick-place.html?m=1

and it seemed like something that could be thrown together in an afternoon (with the right parts on hand) at reasonable cost.

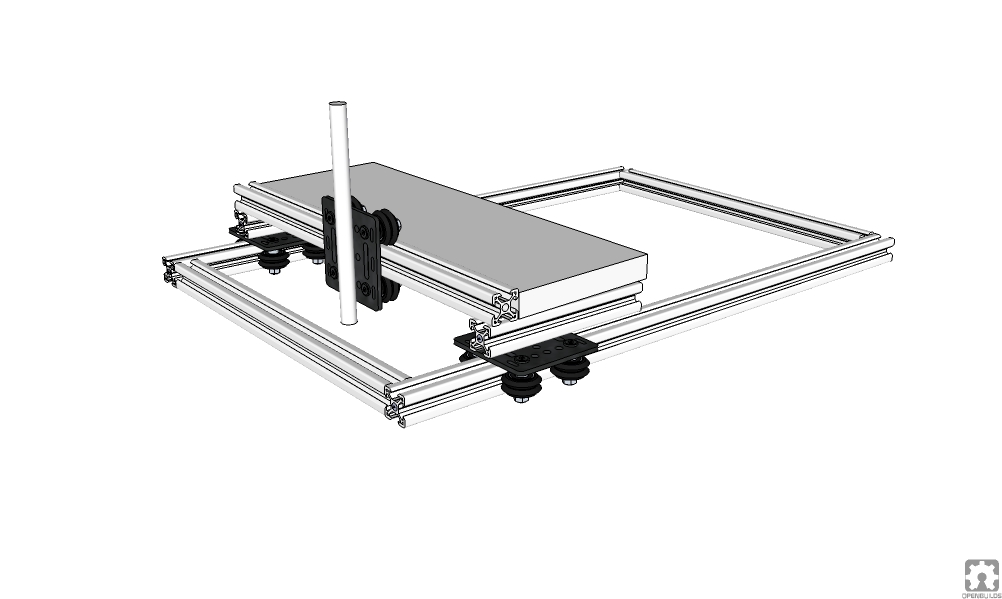

I already have a bunch of 2020 v-slot 2020 extrusion around, so I thougt I'd make mine out of that. I whipped up a quick sketchup to see how it'd look:

Building it out of extruded aluminum is certainly more expensive than SadSack's link, but since I have most parts lying around, it won't be too bad. I just needed a few extra wheels and the gantry plates as well as a better pump, a foot switch and needle bearings. I am still trying to decide how big I need it. I think I'll make mine a little smaller than vpapanik's. roughly 500mmx250mm which should be plenty large for any board I am likely to hand-assemble. Once the spare parts come in, I'll try to throw it together and hopefully have it working before it is time to assemble the next iteration of the UniversalTx board.

I already have a bunch of 2020 v-slot 2020 extrusion around, so I thougt I'd make mine out of that. I whipped up a quick sketchup to see how it'd look:

Building it out of extruded aluminum is certainly more expensive than SadSack's link, but since I have most parts lying around, it won't be too bad. I just needed a few extra wheels and the gantry plates as well as a better pump, a foot switch and needle bearings. I am still trying to decide how big I need it. I think I'll make mine a little smaller than vpapanik's. roughly 500mmx250mm which should be plenty large for any board I am likely to hand-assemble. Once the spare parts come in, I'll try to throw it together and hopefully have it working before it is time to assemble the next iteration of the UniversalTx board.

Please Log in or Create an account to join the conversation.

- SadSack

-

- Offline

Less

More

- Posts: 317

08 Apr 2015 21:21 #30917

by SadSack

Replied by SadSack on topic Buildinga manual pick&Place machine

Looks the part.

I would add a witness guide IE print out of each individual values on pcb. So you know with out thinking where next part goes.

I would add a witness guide IE print out of each individual values on pcb. So you know with out thinking where next part goes.

Please Log in or Create an account to join the conversation.

- PhracturedBlue

-

Topic Author

- Offline

Less

More

- Posts: 4403

12 Apr 2015 23:39 - 13 Apr 2015 01:33 #31124

by PhracturedBlue

Replied by PhracturedBlue on topic Buildinga manual pick&Place machine

I built the p&p frame:

it seems to work well, except for the spring-loaded vacuum tube. The needle bearings don't work really well for sliding in and out. I tried a steel tube instead of aluminum but it didn't help much. So I still need to work on that still. I also need to 3d-print some end caps for the vacuum tube.

I ordered some linear bearings and a matching tube, which will hopefully take care of the issue.

it seems to work well, except for the spring-loaded vacuum tube. The needle bearings don't work really well for sliding in and out. I tried a steel tube instead of aluminum but it didn't help much. So I still need to work on that still. I also need to 3d-print some end caps for the vacuum tube.

I ordered some linear bearings and a matching tube, which will hopefully take care of the issue.

Last edit: 13 Apr 2015 01:33 by PhracturedBlue.

Please Log in or Create an account to join the conversation.

- Cereal_Killer

-

- Offline

13 Apr 2015 04:31 #31127

by Cereal_Killer

Taranis X9E | DEVO 10 | Devo U7E | Taranis Q7

What I do in real life: rivergoequestrian.com/

Replied by Cereal_Killer on topic Buildinga manual pick&Place machine

This looks awesome, I really need one!

Doesn't seem like it would be hard to automate at all (not that it isn't cool / useful enough as is). Please keep us up to date with your build thread, very interested to see how works out for you.

Doesn't seem like it would be hard to automate at all (not that it isn't cool / useful enough as is). Please keep us up to date with your build thread, very interested to see how works out for you.

Taranis X9E | DEVO 10 | Devo U7E | Taranis Q7

What I do in real life: rivergoequestrian.com/

Please Log in or Create an account to join the conversation.

- RoGuE_StreaK

-

- Offline

Less

More

- Posts: 486

14 Apr 2015 04:57 #31151

by RoGuE_StreaK

Replied by RoGuE_StreaK on topic Buildinga manual pick&Place machine

Nice, I've looked up lots of PNP machines before but never heard of a manual one; so it's essentially a slidy arm rest to steady your hand, allowing for better accuracy and speed?

A method of pickup that I saw somewhere, which may or may not be of use to some, is to use a cheap syringe with the end blunted off, and a hole in the side of the body. Vacuum is permanently applied, and you just seal up the hole with your finger to apply vacuum, or release to drop. Obviously you don't want to be running too much vacuum with it, so I guess my 2-stage 29inches pump is out of the question...

A method of pickup that I saw somewhere, which may or may not be of use to some, is to use a cheap syringe with the end blunted off, and a hole in the side of the body. Vacuum is permanently applied, and you just seal up the hole with your finger to apply vacuum, or release to drop. Obviously you don't want to be running too much vacuum with it, so I guess my 2-stage 29inches pump is out of the question...

Please Log in or Create an account to join the conversation.

- PhracturedBlue

-

Topic Author

- Offline

Less

More

- Posts: 4403

14 Apr 2015 14:07 #31170

by PhracturedBlue

Replied by PhracturedBlue on topic Buildinga manual pick&Place machine

yep, that is exactly it. In this case, I use an aquarium pump (which can easily be reversed to a suction pump), so not too much flow. I'm planning to use a foot-switch to control it, because from prior experience I found that any movement of my hand tends to cause jiggle that mis-aligns the part. The vacuum assembly is spring-loaded and can rotate and move in the z-axis, which makes it easy to precisely align parts.

I found that the needle bearings can work ok if you use 2 AND you get them precisely aligned. I did that by abutting them, and now my tube slides easily enough, but I still plan to replace the assembly with linear bearings which should be more precise.

As far as motorizing it, I think this isn't the best design for that. The complication in pick&place is the machine vision which identifies whether the part has been picked up and its orientation. They aren't easy tasks to solve. But for prototyping, I am hopeful this machine will make assembly much less stressful. We'll know in a couple weeks once the next generation of boards come in.

Now that I have all this equipment, I may run another round of multi-module boards using SMT components.

I found that the needle bearings can work ok if you use 2 AND you get them precisely aligned. I did that by abutting them, and now my tube slides easily enough, but I still plan to replace the assembly with linear bearings which should be more precise.

As far as motorizing it, I think this isn't the best design for that. The complication in pick&place is the machine vision which identifies whether the part has been picked up and its orientation. They aren't easy tasks to solve. But for prototyping, I am hopeful this machine will make assembly much less stressful. We'll know in a couple weeks once the next generation of boards come in.

Now that I have all this equipment, I may run another round of multi-module boards using SMT components.

Please Log in or Create an account to join the conversation.

Time to create page: 0.064 seconds

-

Home

-

Forum

-

General

-

General Discussions

- Building a manual pick&Place machine