- Posts: 152

Single-Board Universal Module

- mikemacwillie

-

- Offline

Please Log in or Create an account to join the conversation.

- PhracturedBlue

-

Topic Author

- Offline

- Posts: 4403

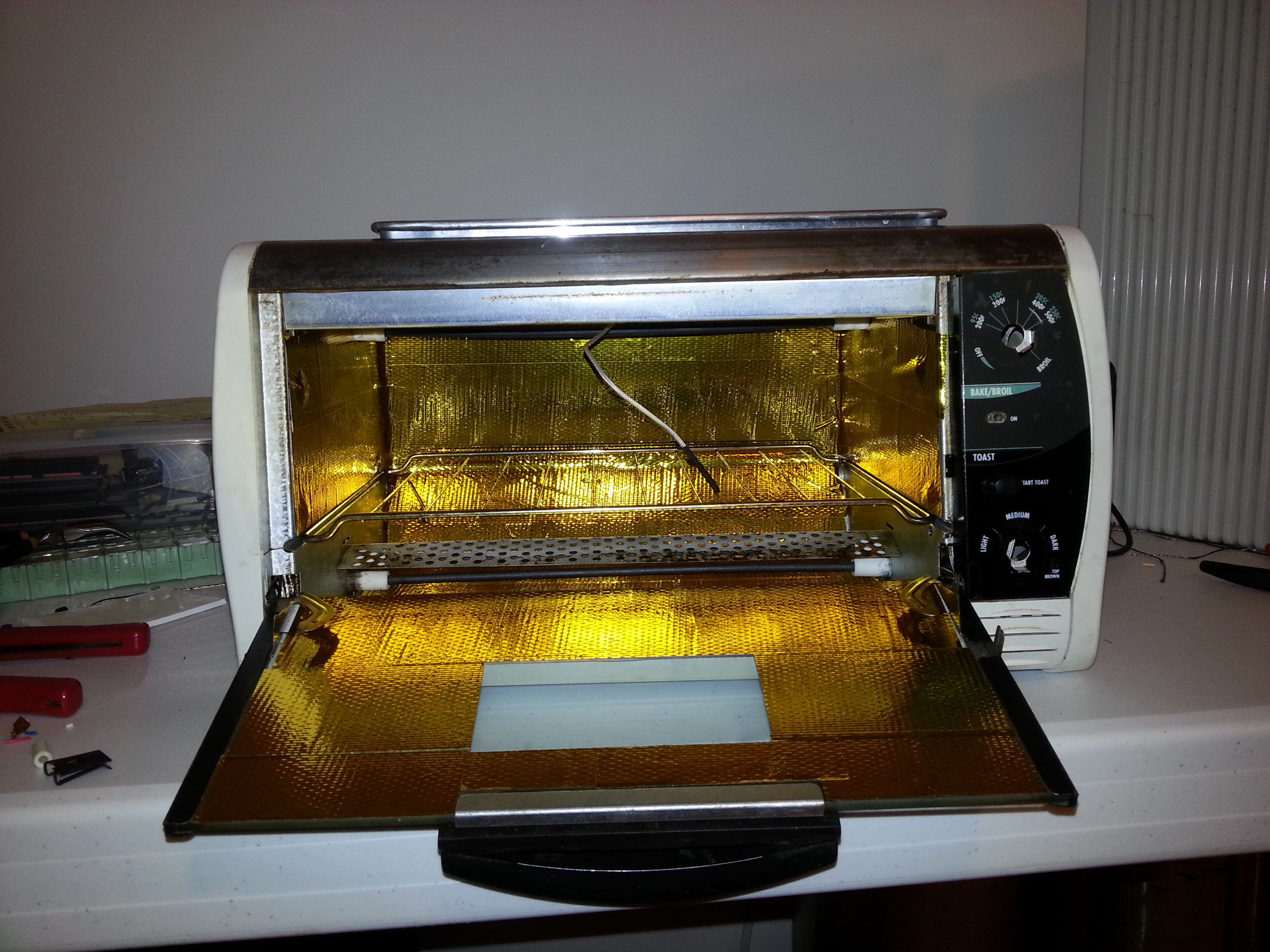

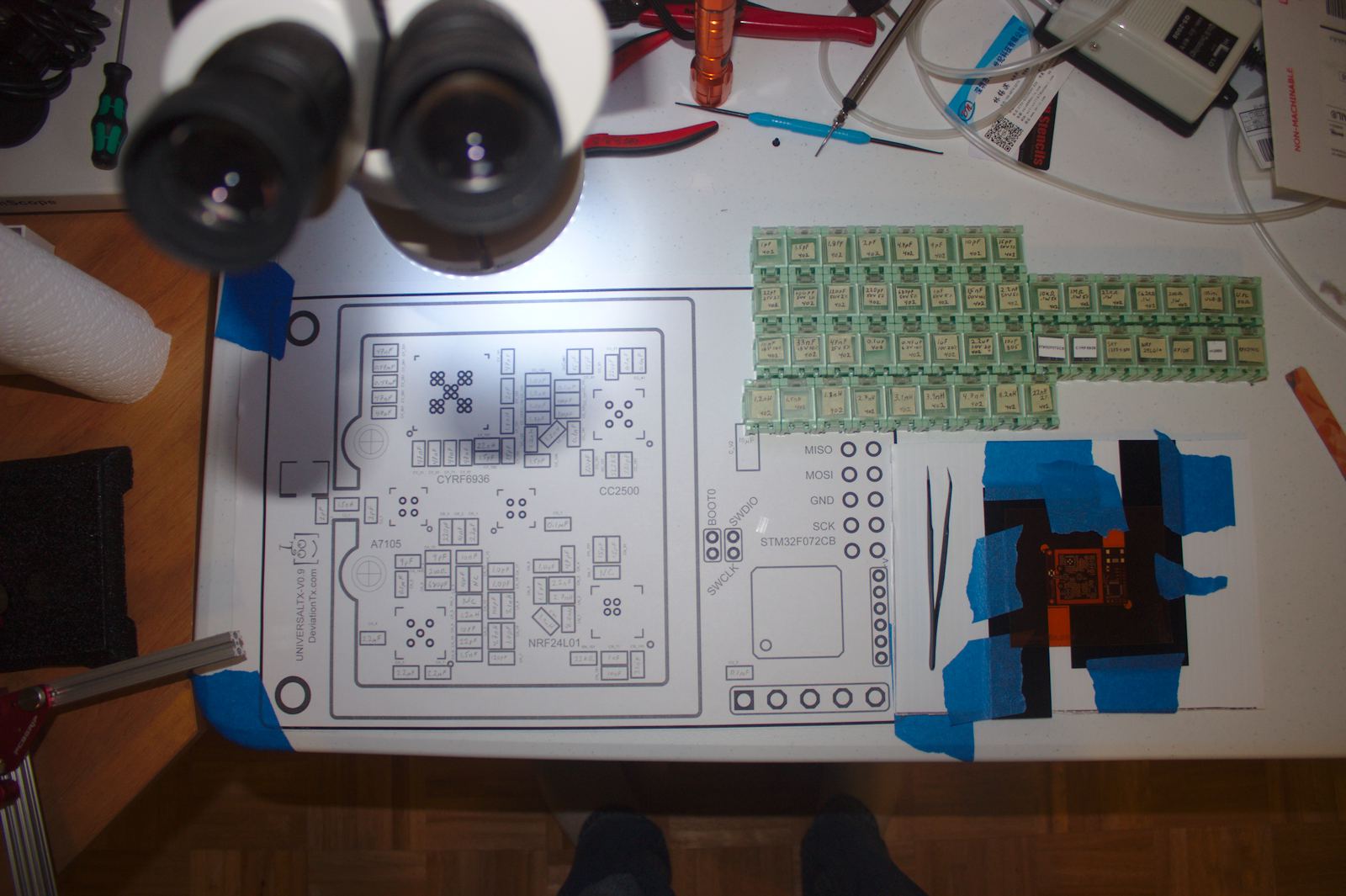

I finished building my reflow oven but I haven't calibrated it yet. Of course I have nearly no idea what I'm doing, so we'll see how assembly goes. Every time I look at the board and how tiny thepads are, I question my sanity.

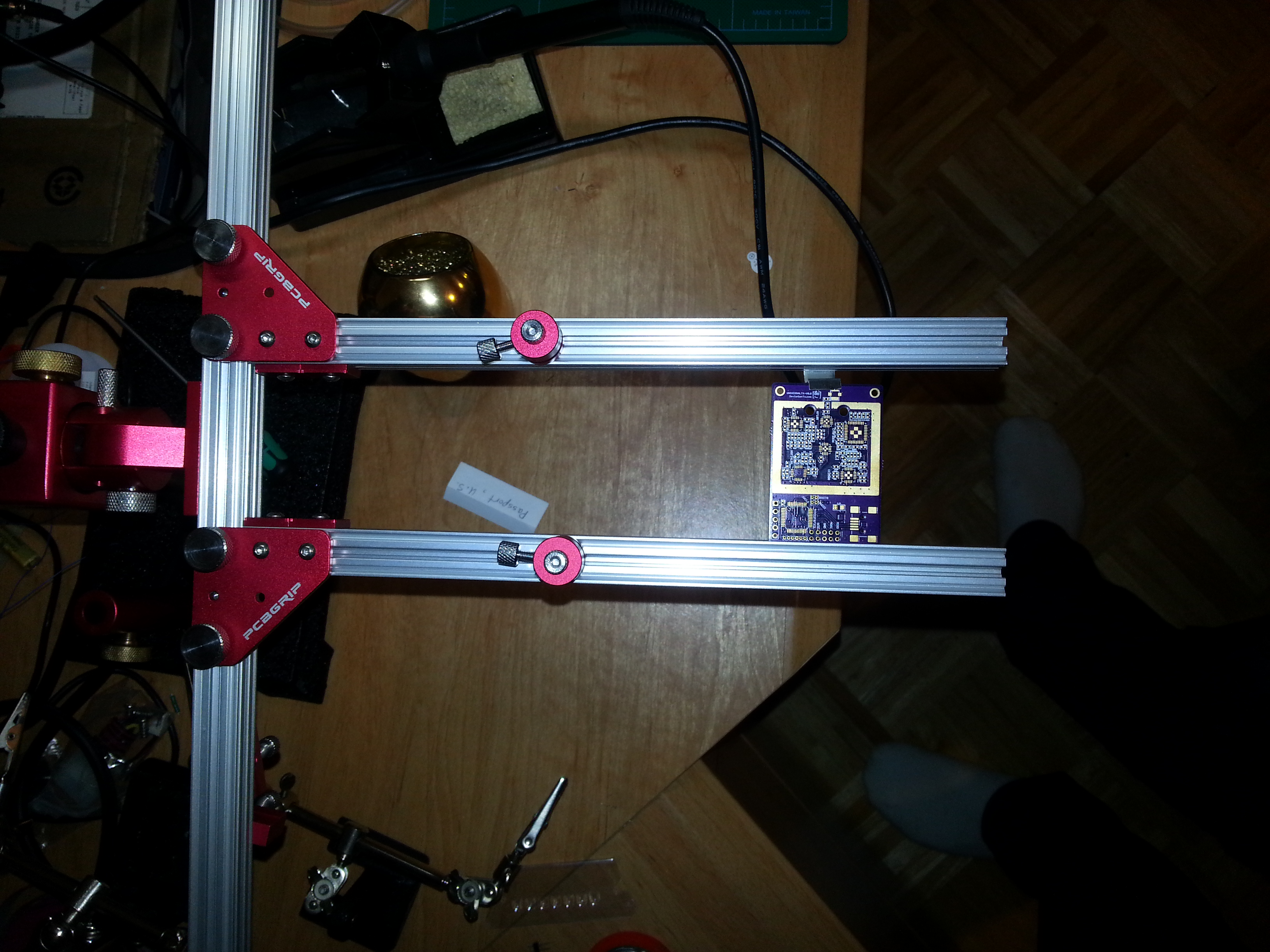

Board in my PCBGRIP jig (I love this jig):

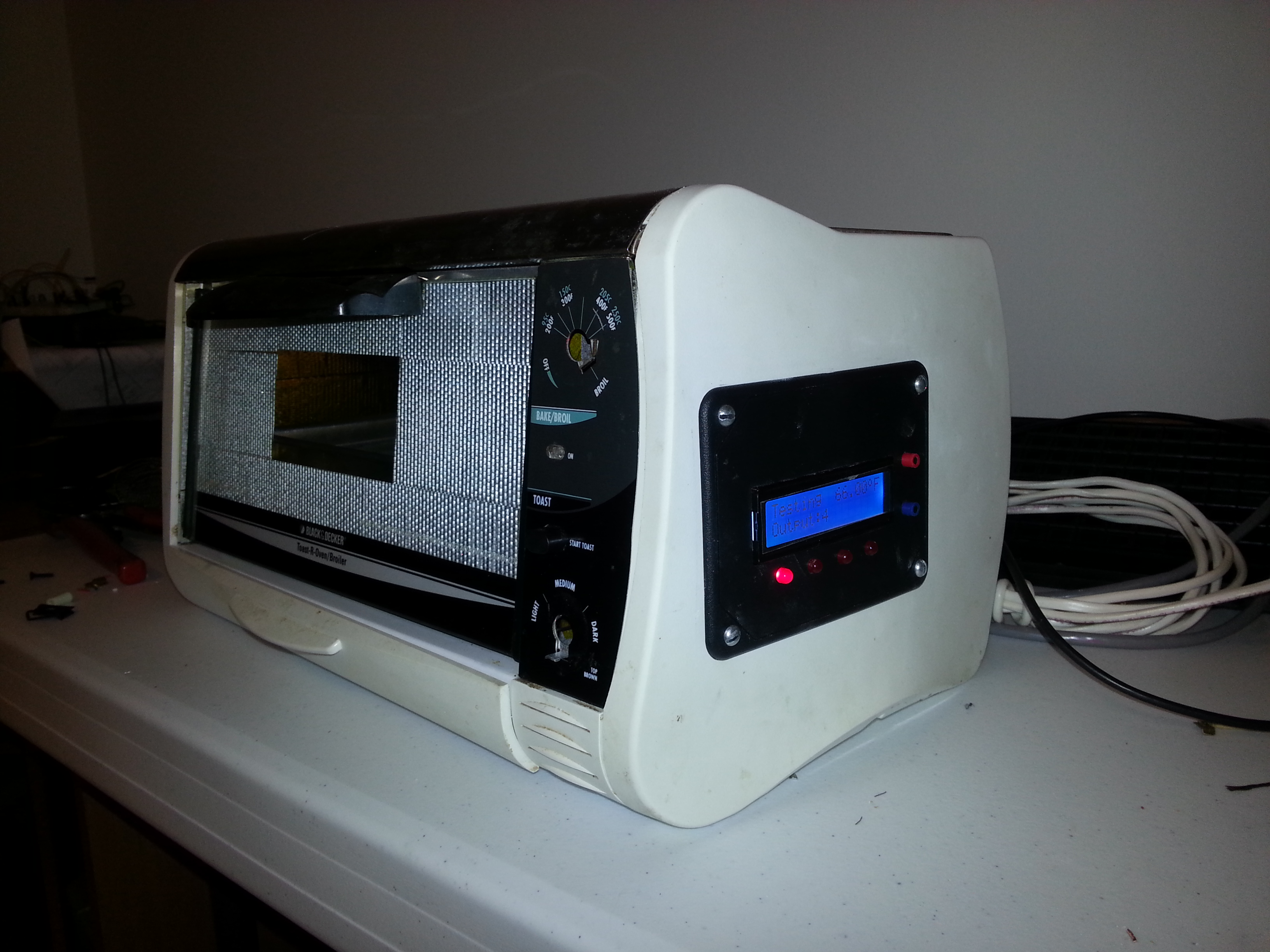

My oven with a ControLeo controller:

Please Log in or Create an account to join the conversation.

- mikemacwillie

-

- Offline

- Posts: 152

That jig looks much nicer than the Panavise I use... Might have to look at buying one of those.

Please Log in or Create an account to join the conversation.

- victzh

-

- Offline

- Posts: 1386

My first board designed and built was very complicated and contained many small RF components. But it worked! I used hot plate and did not calibrate it, I also did not used stencil, so your approach is much more professional and should work better.

Admittedly, your board is many times more complicated than typical RF board, but we hope it's feasible and wish you luck!

Please Log in or Create an account to join the conversation.

- PhracturedBlue

-

Topic Author

- Offline

- Posts: 4403

mikemacwillie wrote: That jig looks much nicer than the Panavise I use... Might have to look at buying one of those.

I had always planned to get a panavise, but then I saw the PCBGRIP. It is really well designed, is very stable, and has lots of attachments that make it easy to hold parts in place for soldering. It is not cheap, but I am so glad I bought it.

I'm still not sure what to do with the bottom of the board. I bought a stencil for it, but my guess is I'll try soldering it by hand. The other option I may explore is using low-temp Bismuth solder (ChipQuik) for the bottom of the board, and reflowing the top 1st using normal leaded solder, then reflowing the bottom at low temperature. The bismuth solders melt at 138C which would likely be fine for everything except maybe the LDO (which is easy to hand-solder).

Please Log in or Create an account to join the conversation.

- mikemacwillie

-

- Offline

- Posts: 152

Please Log in or Create an account to join the conversation.

- PhracturedBlue

-

Topic Author

- Offline

- Posts: 4403

Please Log in or Create an account to join the conversation.

- mikemacwillie

-

- Offline

- Posts: 152

Please Log in or Create an account to join the conversation.

- victzh

-

- Offline

- Posts: 1386

Please Log in or Create an account to join the conversation.

- Fernandez

-

- Offline

- Posts: 983

I recommend to use old style leaded solder with few % silver. Do buy from good supplier (not use chines or no brand nme stuff) and buy fresh stuff. I can tell you it realy makes a difference, it must be fresh for the best flow.

Supply by hand works fine use small needle/syringe, very little bit is enough only at the outerpins of the ic's. i always clean the pcb with some liquid flux before putting the solder paste.

you can use usb microscope to check for solder bridges.

Please Log in or Create an account to join the conversation.

- PhracturedBlue

-

Topic Author

- Offline

- Posts: 4403

Not having done this before, do you do the bottom of the board 1st then? There are only a few elements on the bottom of the board, and they are all either very small or have large solder surface area, so I guess the surface tension should be fine. I would be much more worried about all the qfn parts being upside-down in the oven. If they move, it'll be a mess.victzh wrote: You have an oven, not a hot plate. You actually can just place crystals on the regular soldering paste and they indeed will be kept in place by surface tension. The only extra in this case - the board should be exposed to the heat on both sides, so it should be kept at the corners or by the mounting holes.

Please Log in or Create an account to join the conversation.

- mikemacwillie

-

- Offline

- Posts: 152

Please Log in or Create an account to join the conversation.

- billmester

-

- Offline

- Posts: 215

google "chipbonder".

Helps a lot.

bm

Please Log in or Create an account to join the conversation.

- victzh

-

- Offline

- Posts: 1386

I think crystals and small elements on the bottom is the right way to do it.

Please Log in or Create an account to join the conversation.

- PhracturedBlue

-

Topic Author

- Offline

- Posts: 4403

Anyhow, I've now got everything setup to place the main board. I'll likely wait until tomorrow though and give my shoulders a break.

Please Log in or Create an account to join the conversation.

- mikemacwillie

-

- Offline

- Posts: 152

Sadly my boards didn't arrive before the weekend. I got my stencil on Friday, so hopefully the boards show up next week, so I can knock out my boards on Saturday.

Please Log in or Create an account to join the conversation.

- PhracturedBlue

-

Topic Author

- Offline

- Posts: 4403

Please Log in or Create an account to join the conversation.

- SeByDocKy

-

- Offline

- Posts: 1016

PhracturedBlue wrote: Well, 2 hours of nerve-racking placement, and a very sore neck, and I got the board placed and reflowed. I haven't done a detailed inspection yet, but at 1st glance, it actually looks like it worked really well despite my pushing components all over the place to get things aligned. I only lost 2 components due to tweezer launch, so I'm pretty happy with that. I did find that my stencil is missing a cutout for paste on the rfx2401c and skyworks chip. I didn't have a syringe handy, but was able to scrape a bit of paste onto the pads. Anyhow, I won't be able to actually examine the board until tomorrow, but I think this was pretty good work for today.

Thumbs up

Please Log in or Create an account to join the conversation.

- PhracturedBlue

-

Topic Author

- Offline

- Posts: 4403

Please Log in or Create an account to join the conversation.

- mikemacwillie

-

- Offline

- Posts: 152

I checked over the Eagle files, and there are quite a few clearance errors, but they're all the same signal, so they're not likely an issue. There's a fairly strong possibility that it's a layer registration issue, and the short will be on the internal layers.

Please Log in or Create an account to join the conversation.

-

Home

-

Forum

-

Development

-

Development

- Single-Board Universal Module